How are tote bags made?

Share in:

Content

Fabric bags are completely fashionable right now, people are switching to longer lasting bags and avoiding the use of plastic and synthetic. Not only do they want to make a difference, but they also look great.

Why should we use fabric bags?

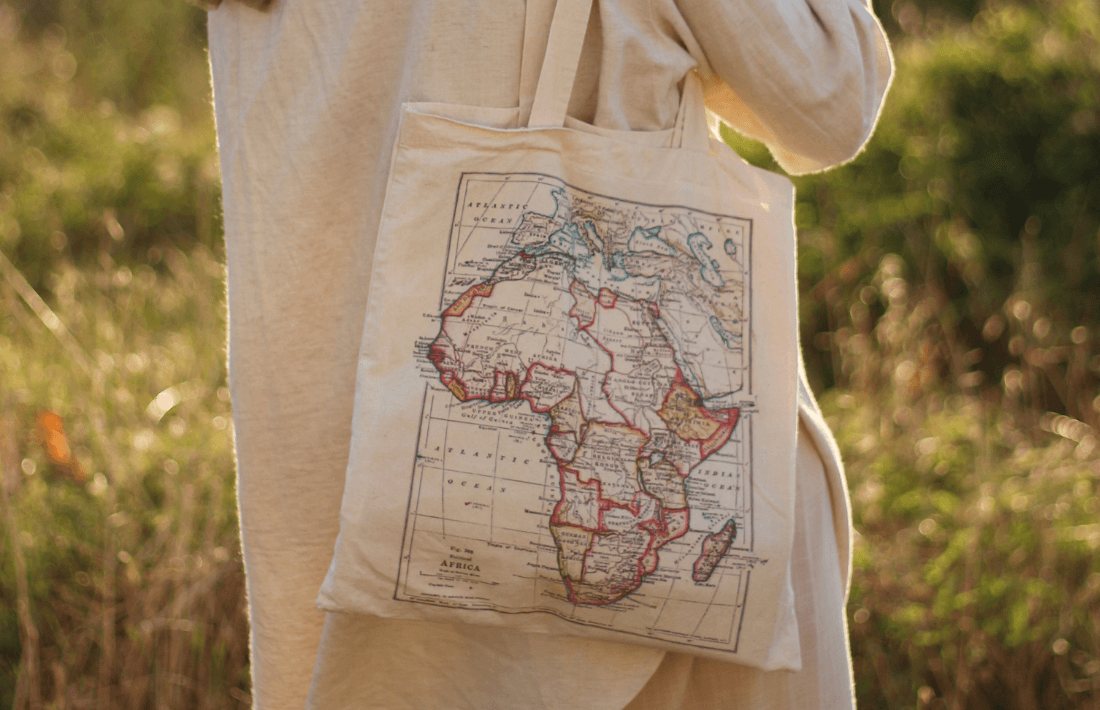

Fabric bags can come in different colors and can often be found stamped or made with custom designs. Currently, blanket bags are everywhere being used for personal, commercial or any other use that is kept in mind.

- Fabric bags can be very durable and with long durability, that’s why they should be made with a very good raw material, take care of the shape and quality of sewing.

- A cloth bag, depending on the size and quality of the material, can carry up to 10-15 kg.

- You can consult with a professional so that your bag carries some personalized printing and with colors.

You can make fabric bags with prints for your business or give it as a gift at your fairs or events.

- Unlike plastic bags or paper bags, their logos will be more consistent in a cloth bag and promote it for a much longer period thanks to its reuse and durability.

- It is also very useful in terms of diversity of handles of fabric bags. You can use single or double shoulder straps, long handles, carry hand handles or short handles to keep it handy.

- Due to the fact that the cloth bags are not transparent; you can store and transport food and beverages, spare shoes, office supplies and all your personal belongings.

- Most importantly, fabric bags are nature-friendly and can be recycled.

Steps to make fabric bags

1). Sketch and pattern

Each bag project begins with a sketch or board that includes inspiration, bag preferences, structure, dimensions.

At this stage is defined the usefulness of the bag, what will be its purpose? Who will use it? This is the basis of an idea that helps determine the best fabric for the bag or the best fastening to close the bag.

Passing the sketch part, it is important to make the pattern of the bag; that is, create the molds either on paper or fabric. These will function as guides for cutting and making.

2). Selected components and fabrics

When calculating how the bag will look, the size it should have, how should it close, and the length straps, then move towards what kind of fabric will be made the bag? What kind of straps will you have? Will there be one or two straps and they are long or short or both?

The choice of fabric will be determined for the purposes of the bag and its budget. You can choose cotton and you can choose from a range of weights, the heavier and thicker the fabric, will generate more investment in the textile.

3). Manual sampling

Sample in person: After asking you questions at the first stage about what the bag wants, what it should contain, the weight it should bear and the size it should have, we will have obtained enough information from you to make a sample of the bag to confirm that it is design and is functional for the uses set out in the sketching.

The sample allows you to see the bag in person. When you receive it, you can show it to your customer for feedback. It is essential that you use it to see if the desired content fits properly.

Color Sample: In some cases, your project will require the fabric to be dyed in a specific shade. It is essential that you validate with your supplier the specifications you require such as Pantone tone, minimum and maximum scales of authorized tones and additional specifications you need.

4). Design revisions

Sometimes, at this stage, small adjustments are made to get the correct final bag. Pockets can be made larger or smaller, enhance reinforcements in the bag, increase or reduce size or add internal compartments to better organize content.

5). Production

After the design is approved and corrected, it is necessary to send to produce according to the quantity necessary to meet the needs and specifications requested, sewing types and product details.

6). Screen printing

Now that the bags are finished, they are ready to be decorated! At this point in the process, your logo will be added to the center of the handbag, usually by screen printing or heat transfer. You can choose one side of the tote bag to display your custom design or level it up and add layouts on both sides.

Follow us on Facebook.